In recent years, the use of clear tubing has surged across various industries, driven by its versatility, durability, and aesthetic appeal. According to a market analysis by Grand View Research, the global clear plastic tubing market is expected to reach USD 1.8 billion by 2027, growing at a CAGR of 5.4% from 2020 to 2027. This growth can be attributed to the increasing demand for clear tubing applications in sectors such as healthcare, food and beverage, and automotive. Clear tubing not only allows for visual monitoring of fluid flow but also ensures compliance with stringent regulatory standards related to health and safety. Innovations in material science are further enhancing the performance and functionality of clear tubing, making it an indispensable component in modern manufacturing and design. This comprehensive guide explores the myriad benefits and applications of clear tubing, shedding light on the innovations that are transforming industry practices.

Clear tubing has become an invaluable asset across various industries due to its unique properties, such as transparency, flexibility, and resistance to chemical reactions. In medical applications, for instance, clear tubing is essential for monitoring fluid flow in IV systems, ensuring healthcare professionals can easily observe and manage dosages with precision. According to a report by Grand View Research, the global medical tubing market is projected to reach $14.2 billion by 2027, highlighting the increasing demand for reliable solutions like clear tubing in healthcare settings.

In the food and beverage industry, clear tubing is crucial for ensuring sanitary processes. It allows for easy visual inspections, which are vital in maintaining hygiene standards. The Food and Drug Administration (FDA) endorses various clear tubing materials, ensuring they meet health requirements. This transparency helps in monitoring contaminants and ensuring product safety, thereby enhancing consumer trust.

Tips: When selecting clear tubing for specific applications, consider factors such as temperature resistance and chemical compatibility. Not all materials are suitable for every environment, so it's essential to consult technical datasheets and verify compliance with industry regulations to choose the right product for your needs. Additionally, routine maintenance and inspection of tubing can prevent issues like leaks, improving the lifespan and reliability of your systems.

Clear tubing has emerged as a vital component in various biomedical applications, enhancing both functionality and safety in medical devices. One of the most innovative uses of clear tubing is in intravenous (IV) systems, where monitoring fluid flow visually can significantly improve patient care. Clinicians can quickly assess the status of IV administration, ensuring that patients receive the correct medication and hydration levels. The transparency of the tubing allows for easy identification of blockages or air bubbles, which can be critical in preventing complications.

In addition to IV applications, clear tubing is gaining traction in the realm of diagnostic equipment. For instance, it is utilized in laboratory setups to connect various components of diagnostic machines. The clarity of the tubing ensures that samples and reagents can be monitored for any anomalies, thereby increasing the reliability of test results. Furthermore, clear tubing now plays a role in innovative microfluidics, where precise fluid manipulation is essential for advanced diagnostic assays and drug delivery systems. As technologies continue to evolve, the versatility of clear tubing in the biomedical field promises exciting developments that can enhance both patient outcomes and the efficiency of medical practices.

| Application Area | Material Type | Advantages | Innovative Techniques |

|---|---|---|---|

| Fluid Delivery Systems | Medical-grade PVC | High clarity allows for easy monitoring of fluid flow | Micro-scale fluid control mechanisms |

| IV Administration | Polyurethane | Flexible and kink-resistant, enhancing patient comfort | Pressure monitoring integrated into tubing |

| Surgery | Silicone | Biocompatible and sterilizable | 3D printing of customized tubing shapes |

| Diagnostic Equipment | Polyethylene | Optically clear for easy visual inspection | Integration with sensor technology |

| Bioreactors | CPE (Clear Polyethylene) | Allows for continuous monitoring of bioprocesses | Smart monitoring solutions to track microbial growth |

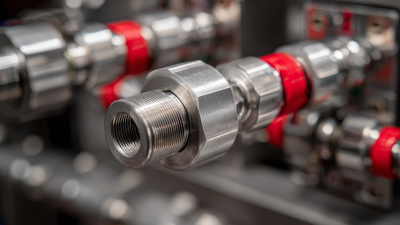

When selecting clear tubing for your specific applications, it’s essential to consider both the diameter and material. The right diameter ensures optimal flow rates and pressure compatibility, which is critical in applications ranging from aquarium setups to medical devices. Standard diameters include 1/4", 1/2", and 3/4", but it's vital to measure the dimensions of your fittings and ensure a proper fit to avoid leaks or pressure drops.

Tips: Always consult manufacturer specifications to understand the flow rate associated with different diameters. Using tubing that is too small can restrict flow and lead to operational issues, while tubes that are too large may not provide the necessary structural support.

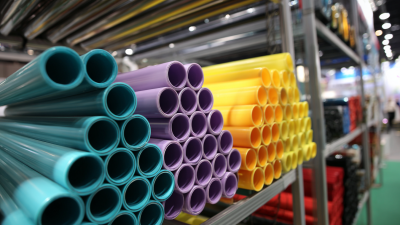

Material choice is equally important. Common materials for clear tubing include PVC, silicone, and polyurethane, each offering unique benefits. PVC is robust and cost-effective, making it suitable for general use, while silicone offers flexibility and durability in temperature-variable environments. Consider the chemical compatibility of the tubing material with the substances it will transport, as well as its temperature tolerance.

Tips: When in doubt, conduct a compatibility test for both the materials and the intended application, ensuring safety and performance without unexpected failures.

Clear tubing has become an innovative choice in various applications, not just for its functionality but also for its aesthetic appeal. From plumbing to decorative uses, clear tubing offers a sleek and modern look that can enhance any project. According to industry reports, the global clear plastic tubing market is projected to witness significant growth, driven by its versatility and the increasing demand for visually appealing designs in both residential and commercial settings.

When considering design tips for incorporating clear tubing, it's essential to focus on the balance between aesthetics and practicality. For instance, installations in home interiors—such as clear tubing for lighting or decorative fixtures—can create an elegant and open feel. Reports indicate that projects utilizing clear materials can see a 20% increase in perceived value, which underscores the importance of thoughtful design choices. Moreover, in environments like aquariums or irrigation systems, clear tubing not only serves a functional purpose but also contributes to a visually striking setup.

In addition to safety design elements like grill gates, integrating clear tubing into architecture and product design can significantly elevate the overall visual appeal while ensuring safety and performance. As consumers increasingly prioritize both aesthetics and functionality, clear tubing stands at the intersection of design ingenuity and practical application.

Maintaining the performance and longevity of clear tubing is crucial for various applications, particularly in fluid transportation and industrial processes. Implementing systematic maintenance strategies can significantly reduce failures and minimize associated costs. One effective approach is to regularly inspect the tubing for signs of wear and tear, ensuring that any potential issues are addressed before they lead to operational downtime. By proactively monitoring the condition of clear tubing, operators can extend its lifespan, much like the recent evidence-based initiatives that enhance the longevity of sucker rods.

Moreover, innovative maintenance techniques such as routine cleaning and replacement of seals can further improve the efficiency of clear tubing systems. These practices not only enhance fluid flow but also prevent clogging and contamination that could compromise system performance. Adopting a comprehensive maintenance schedule, supported by data-driven insights, ensures that clear tubing remains functional over extended periods, thereby optimizing operational efficiencies and reducing overall costs. By focusing on these maintenance strategies, industries can harness the benefits of clear tubing while ensuring its reliability in critical applications.

This bar chart illustrates the various applications and innovations of clear tubing, highlighting its common uses and benefits in different sectors.