In the competitive landscape of industrial applications, the choice of materials can greatly influence operational efficiency and cost-effectiveness. One material that has garnered immense popularity is the carbon steel pipe, lauded for its strength, durability, and versatility. According to industry expert John Smith, a leading engineer at Steel Solutions, “The superior mechanical properties of carbon steel pipes make them an ideal choice for a wide range of industrial applications, from oil and gas to construction and manufacturing."

As industries continue to evolve, the benefits offered by carbon steel pipes become increasingly apparent. Their ability to withstand high pressure and temperature settings ensures reliability, while their relatively low cost makes them an economically feasible option for many projects. In addition, carbon steel pipes can be easily welded and fabricated, further enhancing their suitability for diverse applications.

This article explores the top seven benefits of using carbon steel pipes in industrial contexts, providing insight into why these pipes remain a favored choice among engineers and manufacturers alike. With a deeper understanding of these advantages, professionals can make informed decisions to optimize their operational strategies and enhance project outcomes.

Carbon steel pipes are increasingly recognized for their durability and strength, making them a preferred choice in various industrial applications. One of the primary benefits of carbon steel pipes is their ability to withstand high pressures and extreme temperatures, which is crucial for industries such as oil and gas, construction, and manufacturing. Their resistance to wear and tear ensures a longer service life, resulting in reduced maintenance costs and increased reliability over time.

Additionally, the structural integrity of carbon steel pipes contributes to safer industrial environments. Their robust nature reduces the risk of leaks and failures, which can have catastrophic consequences. Moreover, the adaptability and cost-effectiveness of carbon steel make it an appealing option for businesses looking to optimize their resources. As the global carbon steel market continues to grow, driven by infrastructure development and industrial expansion, the benefits of using carbon steel pipes will remain a significant factor for industries striving for efficiency and sustainability.

When evaluating materials for industrial applications, the cost-effectiveness of carbon steel pipes stands out remarkably. Compared to alternatives like stainless steel, carbon steel pipes offer a more affordable upfront investment without significantly compromising on performance. Their robust nature ensures longevity and durability, which translates to lower replacement and maintenance costs over time. This financial advantage is particularly appealing for businesses looking to optimize their budget while maintaining operational efficiency.

Tips: When selecting carbon steel pipes, consider the specific environmental and operational conditions they will face. Ensuring compatibility with your application will prevent costly failures and extend the lifespan of your infrastructure.

In addition to initial cost savings, carbon steel pipes also demonstrate superior strength and pressure tolerance, making them ideal for high-demand applications. Industries focused on energy infrastructure can greatly benefit from utilizing carbon steel, as ongoing research and innovative metallurgical solutions enhance their performance capabilities. This positions carbon steel as a reliable choice amid increasing energy demands and evolving market trends.

Tips: Always consult with material specialists when choosing pipes for specific industrial applications. They can provide insights about the most suitable grades and ensure that you leverage the full benefits of carbon steel pipes in your projects.

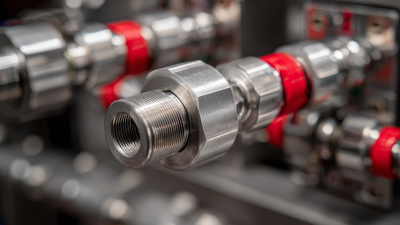

Carbon steel pipes are increasingly favored in industrial applications due to their impressive resistance to high temperatures and pressures. This characteristic makes them ideal for environments where traditional materials might fail.

With the ability to withstand extreme conditions without significant deformation or loss of structural integrity, carbon steel pipes ensure safety and reliability in operations involving steam, gas, and other high-pressure systems.

When using carbon steel pipes, it's essential to consider

proper insulation, especially in high-temperature applications. Insulating the pipes can help maintain temperature levels, reduce heat loss, and prevent condensate formation, which could lead to corrosion. Additionally, regular maintenance checks can significantly enhance the longevity of these pipes, allowing for early detection of any potential wear or structural weaknesses.

Moreover, selecting the right grade of carbon steel is crucial for optimal performance. Different grades offer varying levels of strength and resistance to heat, so assess the specific requirements of your application carefully. Implementing these tips can lead to significant improvements in efficiency and the overall lifespan of the piping systems, ensuring that industrial operations run smoothly and safely.

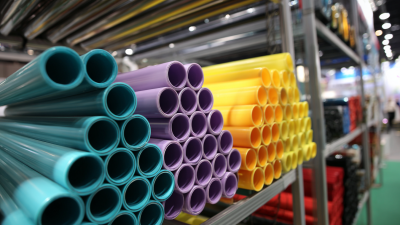

Carbon steel pipes are increasingly recognized for their versatility across a wide array of industrial applications. Their inherent strength and durability make them suitable for demanding environments such as oil and gas, construction, and manufacturing. The ability to withstand extreme pressure and temperature conditions also enhances their appeal, allowing them to be used effectively in critical infrastructure projects. Additionally, carbon steel pipes are available in various grades and specifications, further expanding their usability in diverse fields.

The adaptability of carbon steel pipes to different manufacturing techniques, such as extrusion and piercing, ensures that they meet specific requirements for various industrial uses. From transporting fluids and gases to serving as structural components, these pipes demonstrate an impressive range of applications. Moreover, advancements in pipe coatings enhance their resistance to corrosion and wear, increasing their longevity and performance. This versatility not only drives efficiency in production processes but also contributes significantly to cost-effectiveness in industrial operations.

| Benefit | Description | Common Uses |

|---|---|---|

| High Strength | Carbon steel pipes offer exceptional strength, making them ideal for high-pressure applications. | Oil and gas pipelines, structural supports |

| Cost-Effectiveness | They provide a cheaper alternative compared to stainless steel and other materials without compromising quality. | Construction, manufacturing |

| Versatility | Carbon steel pipes can be used in a variety of applications across different industries. | Water supply, HVAC systems |

| Weldability | Easily weldable, which facilitates the construction of complex structures. | Fabrication, repair operations |

| Durability | They are resistant to wear and tear, which enhances their longevity in industrial settings. | Industrial machinery, infrastructure |

| High Heat Resistance | Can withstand high temperatures, making them suitable for heating applications. | Boilers, heat exchangers |

| Corrosion Resistance | When galvanized, carbon steel pipes are resistant to rust and corrosion. | Water distribution, irrigation |

When it comes to industrial applications, carbon steel pipes are renowned for their durability and performance; however, their ease of maintenance and repair is equally crucial. According to a report by the American Society of Mechanical Engineers (ASME), maintenance costs can account for up to 40% of the total operational expenses in industrial settings. Carbon steel pipes significantly reduce these costs due to their straightforward maintenance requirements, such as simple inspection protocols and accessible repair techniques. This allows operators to minimize downtimes and enhance productivity, ensuring that systems remain operational longer.

Moreover, the availability of various linings and coatings for carbon steel pipes makes them highly adaptable to different environmental conditions and service requirements. A study conducted by the International Pipeline and Subsea Engineering Society revealed that proper maintenance of carbon steel pipe systems can extend their lifespan by up to 30%. The materials can often be easily welded or patched up without extensive downtime. This adaptability not only translates to lower repair costs but also promotes a proactive maintenance culture where potential issues can be addressed swiftly, ensuring seamless industrial operations.

This bar chart illustrates the top seven benefits of using carbon steel pipes in industrial applications. The data highlights cost-effectiveness, strength, durability, ease of maintenance, corrosion resistance, versatility, and recyclability as the key advantages, showcasing their importance in industrial settings.