In the complex world of fluid dynamics, relief valves play a vital role. Experts like Dr. Emily Carter emphasize their importance, stating, “A reliable relief valve is crucial for any system's safety.” With the right choice, you can prevent costly failures and ensure maximum efficiency in your operations. However, selecting the best relief valve isn't always straightforward.

There are numerous options available, each designed for different applications. The characteristics of pressure, temperature, and media all influence your choice. Many users face confusion over specifications. It's easy to overlook important details when making a selection.

Think about how a small oversight can lead to serious issues. The wrong pressure settings or materials can result in frequent failures. Therefore, understanding the various relief valve types is essential. This knowledge is your first step toward making an informed decision.

Relief valves play a crucial role in various systems, ensuring safety and functionality. These devices are designed to release excess pressure, preventing potential system failures. They are common in industries like manufacturing, plumbing, and even in vehicles. A relief valve opens at a predetermined pressure, allowing fluid or gas to escape. This process maintains safe operating levels.

When selecting a relief valve, consider your system's requirements. Evaluate the pressure settings and the type of media involved. Ensure compatibility with your system's materials. Mistakes in choosing the right valve can lead to costly failures.

Tips: Always install the valve in a location that allows easy access for maintenance. Routine checks can prevent issues later. Keeping a log of your system's pressure patterns may also highlight any irregularities. This careful monitoring is essential for optimal performance. Remember, even small leaks can signal larger problems ahead.

This chart displays the performance characteristics of various relief valve types based on their flow capacity (Cv) and operating pressure (psi). The data provides insight into how different valve designs cater to specific industrial requirements.

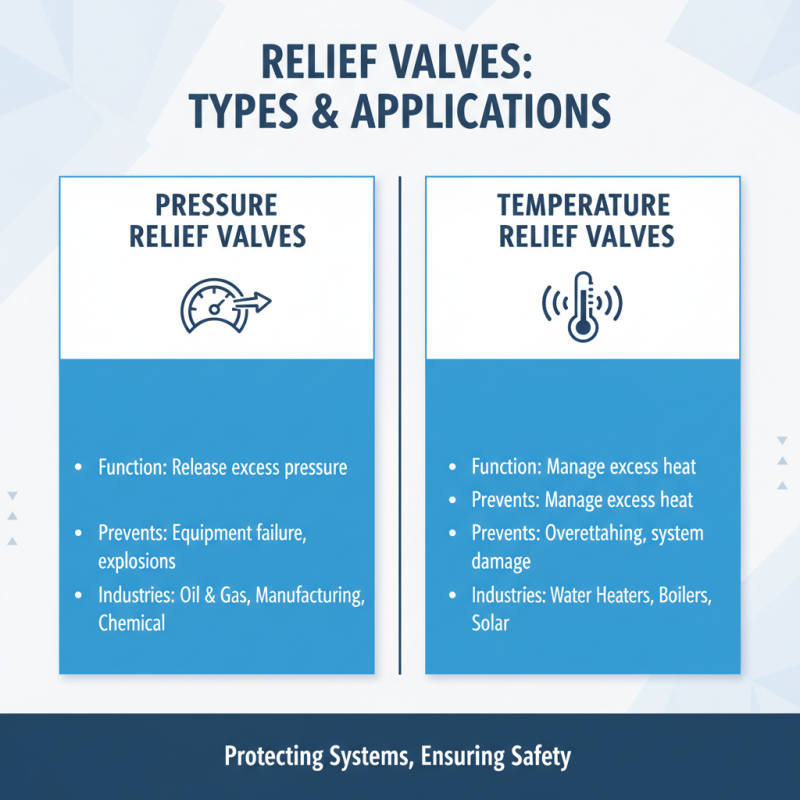

When exploring relief valves, it’s essential to understand the common types and their applications. There are several varieties. Each serves a specific function. Pressure relief valves allow excess pressure to escape. This helps prevent equipment failure. They are crucial in various industries. Another type is temperature relief valves. These help manage heat in systems to avoid overheating.

Tip: Always assess your system’s needs before selecting a relief valve. The right choice ensures safety and efficiency.

Another common type is pilot-operated relief valves. These provide precise control over pressure settings. They are often used in larger systems with fluctuating pressures. Spring-loaded relief valves are also popular. They are straightforward and reliable for various applications. However, they may not be ideal for dynamic systems.

Tip: Regular maintenance of relief valves is vital. Wear and tear can lead to malfunction. Make it a habit to inspect and replace as necessary. Understanding these types can lead to better decision-making for your specific needs.

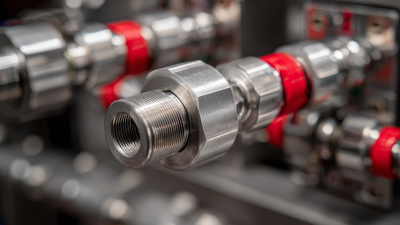

When selecting a relief valve, several key factors should guide your decision. Pressure ratings are crucial. Most applications require valves to handle pressures up to 3000 psi. However, some systems may go higher. It's essential to know the maximum pressure your system can face. This will help prevent potential failures.

Material selection is another critical aspect. Common materials include stainless steel and brass. Each material has its advantages. For example, stainless steel offers better corrosion resistance. In contrast, brass is often more cost-effective. According to industry reports, 40% of premature valve failures result from improper material use. Thus, choosing the right material can significantly improve performance.

Flow rate is also vital in choosing the right valve. Ensure the valve can handle your required flow without restrictions. Sizing errors could lead to safety issues. Studies indicate that nearly 30% of systems fail due to incorrect valve sizing. Take the time to assess your needs clearly. Ultimately, a well-chosen relief valve can enhance safety and ensure optimal operation.

Choosing the right relief valve can be challenging. A variety of brands and models exist on the market. Each has unique features tailored to different needs. Understanding these options is crucial for making informed decisions.

One common problem is the lack of detailed information. Many users struggle to find reliable reviews. Some models may not meet high performance standards. Users often overlook factors like material quality and design efficiency. These details significantly impact performance and safety in various applications.

When evaluating relief valves, consider their pressure settings. Some models offer adjustable settings for different operations. This flexibility can be beneficial in dynamic environments. Also, take note of user feedback. Real-world experiences can highlight the pros and cons of each option. However, not every review is trustworthy. Use discernment when sifting through opinions.

| Model | Pressure Rating (psi) | Material | Size (inches) | Temperature Range (°F) | Application |

|---|---|---|---|---|---|

| Model A | 1500 | Stainless Steel | 1" | -20 to 250 | Water & Steam |

| Model B | 3000 | Brass | 3/4" | -10 to 300 | Gas & Oil |

| Model C | 2500 | PVC | 2" | 0 to 140 | Chemical Processing |

| Model D | 1800 | Aluminum | 1.5" | -40 to 200 | Air & Gas |

| Model E | 2000 | Carbon Steel | 2.5" | -10 to 300 | Oil & Gas |

Maintenance is crucial for relief valves. Regular checks prevent unexpected failures. Ensure that the valves are free from debris. Dirt can cause blockages. Inspect the seals for signs of wear. Replacing damaged seals is essential for proper function.

Periodic testing is also important. Conduct functional tests to confirm performance. Look out for any unusual noises during operation. These can indicate underlying issues. Keep an eye on the pressure settings. Incorrect pressures can lead to valve malfunction.

Documentation is key to tracking maintenance actions. It's easy to forget when maintenance was last performed. A simple log can help. Review it regularly. Share insights with your team for better outcomes. Valves don't just operate themselves. They need your attention.