In industrial settings, the safety valve plays a crucial role. It prevents overpressure scenarios, protecting equipment and personnel alike. Choosing the right safety valve can be complex. Various factors influence their effectiveness, such as design, material, and application.

The market is evolving rapidly. By 2026, new advancements and options are expected. Industrial operators must remain vigilant in selecting the best safety valves. Poor choices can lead to equipment failure or catastrophic incidents.

Understanding the nuances of safety valves is vital. Each application demands specific features. As technology progresses, so do the challenges. Operators must stay informed and adaptable. This proactive approach ensures safety and efficiency in industrial operations.

Safety valves play a crucial role in industrial applications. They ensure pressure control and prevent equipment failures. In 2023, the global market for safety valves was valued at approximately $3.5 billion, with a projected growth of over 5% annually through 2026. This highlights their importance in various sectors like oil and gas, chemical processing, and power generation.

The design and functionality of safety valves are vital in mitigating risks. They act as a protective measure against overpressure. Many industries still rely on outdated models that may not meet current safety standards. Recent studies indicate that nearly 30% of safety valve installations are not operating at optimum levels. This inefficiency can lead to significant safety hazards and financial losses.

Regular maintenance is essential for ensuring optimal performance. However, many facilities overlook this aspect. In fact, a shocking 45% of safety valves have never been inspected after installation. This neglect raises questions about long-term safety and reliability. Industries must prioritize training and compliance to enhance the functionality of safety valves in their operations.

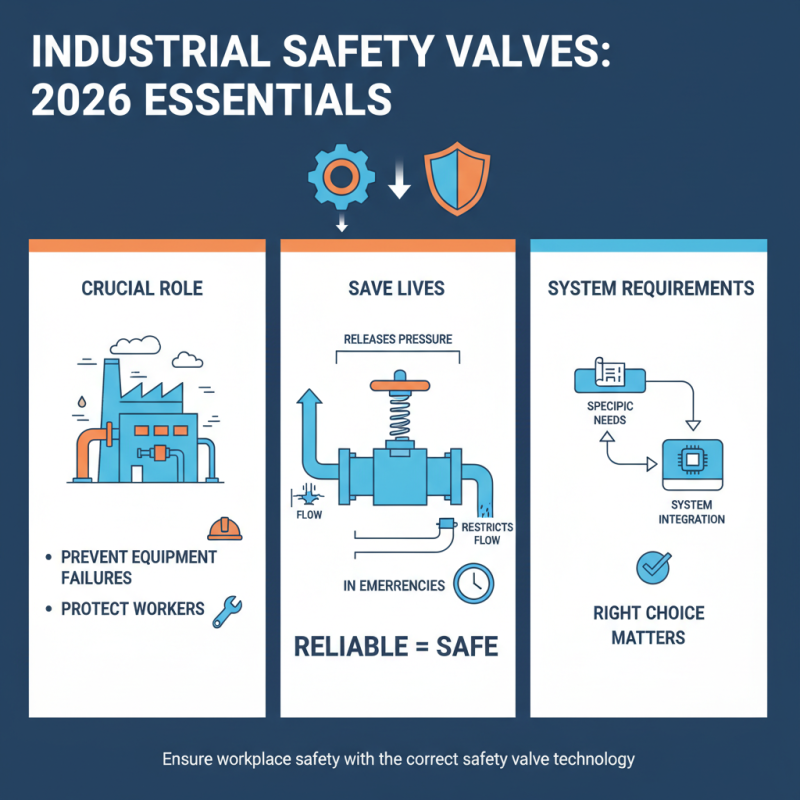

When selecting safety valves for industrial applications, several key features are vital.

Pressure ratings are crucial. Many industries operate under specific pressure conditions. A valve must be rated appropriately.

For example, valves with a rating of 350 PSI are common in oil and gas. Those for pharmaceutical applications may need to handle lower pressures but with higher precision.

Another important aspect is the material of construction. Different industries require different materials to withstand diverse environments.

Stainless steel valves are prevalent in food and beverage processing. They resist corrosion well. However, not all stainless steel compositions are the same.

Some may not endure high-temperature applications well, leading to premature failure. Choosing the wrong material could result in significant risk or downtime.

Lastly, the valve's size plays a critical role. Oversized valves can impact system efficiency. A report from the American Society of Mechanical Engineers indicates that improperly sized safety valves account for 30% of operational failures.

Conversely, undersized valves may not relieve pressure adequately, posing safety hazards. Often, many overlook these sizing details. Proper selection requires careful analysis and understanding of system dynamics.

In 2026, safety valves are crucial for industrial applications. These devices prevent equipment failures and protect workers from hazards. A reliable safety valve can save lives. They often release pressure or restrict flow in case of emergencies. The right choice depends on specific needs and system requirements.

When selecting safety valves, it's important to consider materials and sizing. Stainless steel is common due to its durability. Many industries require high-temperature and high-pressure ratings. However, not all valves meet these conditions adequately. It's wise to evaluate the valve’s performance data closely before making a decision.

Installation and maintenance are other critical aspects. A poorly installed valve can lead to leaks or failures. Regular checks ensure functionality and safety. Many industries fail to prioritize these inspections, leading to potential risks. A focus on these details can lead to better operational safety.

When selecting safety valves for industrial applications, quality is paramount. The market has many options, yet not all deliver equally. It's crucial to compare the features and performance of different brands. Some valves excel in pressure relief capabilities, while others focus on durability. Understanding these differences can help in making the best choice.

Materials used in the construction of safety valves significantly impact their effectiveness. Most valves are made from stainless steel, but some incorporate other metals to enhance performance. Testing under extreme conditions reveals flaws. For example, certain valves may fail to open at required pressures. Factors like maintenance frequency also need consideration. Regular inspections can reveal wear and tear that leads to malfunctions.

In the comparative analysis of leading brands, some stand out for their reliability. However, others may seem appealing but lack consistent performance. User feedback often highlights issues like installation difficulties or poor customer support. These elements are essential to consider when evaluating options. It’s not just about purchasing a valve; it's about ensuring it performs well in real-world scenarios.

As industries evolve, safety valve technology must keep pace. In 2026, we anticipate significant advancements in the design and functionality of safety valves. Smart technologies are on the rise. These valves will feature sensors that provide real-time data. This data will help prevent overpressure incidents before they happen.

Tips: Regular maintenance is crucial. Check for wear and tear. Early detection can save costs and prevent failures. Also, consider training staff on handling new technologies. Awareness leads to better safety practices.

Future trends will likely include improved materials. High-performance alloys can enhance durability and resistance to harsh conditions. The integration of IoT will create connected systems. These systems can alert operators of any anomalies quickly. However, integrating new technology can be challenging. Budget constraints might hinder upgrades. Companies must balance innovation with practicality.

Tips: Involve users in the testing phase. Their feedback can clarify needed improvements. Create a culture of safety that encourages open communication. This can lead to better adoption of new safety technologies.

This chart illustrates the importance rating of various features for safety valves in industrial applications predicted for 2026. Each feature's rating reflects its significance in ensuring industrial safety and efficiency.