Choosing the right gas hose is a critical decision for ensuring safety and efficiency in various applications, whether for home use or industrial purposes. A gas hose acts as a conduit for transporting gases, and its importance cannot be overstated. With numerous options available in the market, selecting a hose that meets your specific needs requires careful consideration of factors such as material, size, pressure rating, and compatibility with the intended gas type. The wrong choice can lead to leaks, inefficiencies, and even hazardous situations.

In this guide, we will delve into essential safety guidelines and practical tips that will empower you to make an informed decision when selecting a gas hose. Understanding the characteristics of different gas hoses, along with their appropriate applications, is crucial for maintaining safe operational standards. From recognizing the signs of wear and tear to learning the best installation practices, this article aims to provide you with a comprehensive overview of how to choose the right gas hose tailored to your requirements. Ultimately, prioritizing safety and functionality will ensure a seamless experience in your gas handling activities.

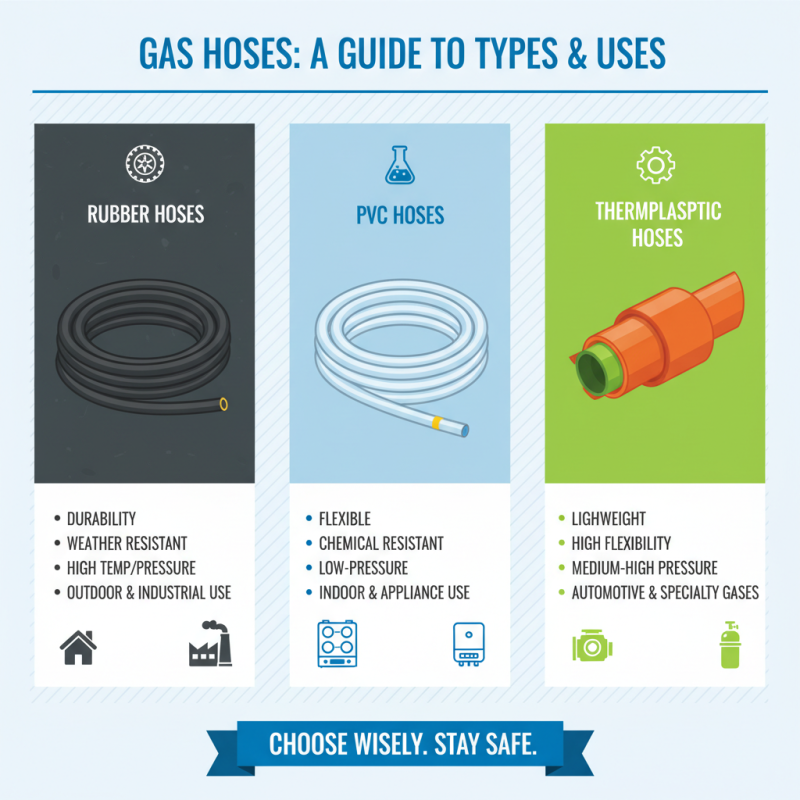

When selecting a gas hose, it's crucial to understand the different types that are available in the market, as each type serves specific applications and safety needs. The most common types include rubber, PVC, and thermoplastic hoses. Rubber gas hoses are known for their durability and resistance to weathering, making them ideal for outdoor use. They can withstand high temperatures and pressures, which is essential for many gas applications, from home installations to industrial uses.

PVC hoses are lightweight and easy to handle, often used in residential settings for appliances like grills and heaters. They are flexible and less expensive, but they may not provide the same level of durability as rubber hoses, especially in extreme conditions. In contrast, thermoplastic hoses offer a balanced option with good flexibility and temperature resistance. They can handle a wide range of gases and are suitable for both indoor and outdoor applications, providing a versatile choice for various users.

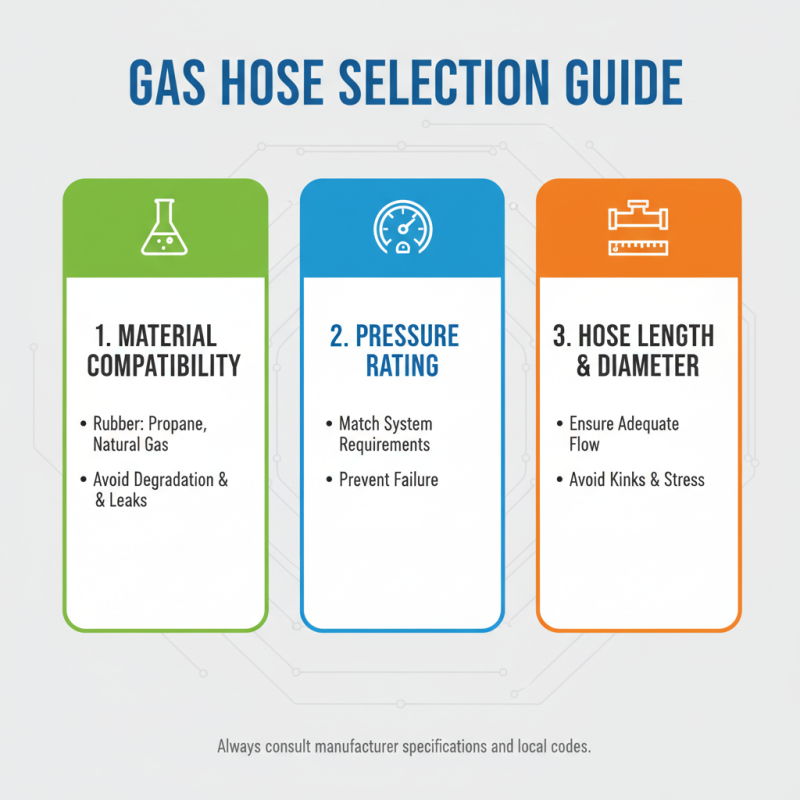

Another important aspect to consider is the hose's pressure rating and diameter. The pressure rating indicates the maximum amount of pressure the hose can safely handle, while diameter affects the flow rate of the gas. Ensuring that the hose is compatible with the appliances and the specific gas type you intend to use is paramount for maintaining safety and efficiency during operation. Proper selection based on these factors can lead to safer and more effective gas usage.

When selecting a gas hose, it's crucial to consider several key factors that directly affect safety and functionality. First and foremost, the hose material must be compatible with the type of gas being transported. For instance, rubber hoses are commonly used for propane and natural gas due to their flexibility and resistance to temperature variations. According to a report from the American Gas Association, using the incorrect material can lead to degradation and leaks, posing significant safety risks. Furthermore, the working pressure rating of the hose must align with the system’s requirements; hoses that are over-pressurized can fail and result in dangerous situations.

Another important consideration is the diameter of the gas hose, which should match the flow requirements for the specific application. A study by the National Fire Protection Association indicates that undersized hoses can restrict gas flow, leading to inefficient operation or even system failure. Additionally, length plays a role; longer hoses can lead to increased pressure drops, affecting performance. Regular inspections for wear and tear are also essential, as hoses can deteriorate over time due to environmental factors. Following these guidelines ensures not only efficient gas transport but also enhances overall safety in operations involving gas systems.

When selecting a gas hose for various applications, adhering to safety standards and regulations is paramount. According to the National Fire Protection Association (NFPA), the correct selection and use of gas hoses can significantly reduce risks associated with gas leaks and explosions. This emphasizes the importance of utilizing hoses that meet industry specifications such as the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM). Compliance with these standards ensures that the hoses can withstand the pressures and chemical properties of the gases they are intended to transport, ultimately enhancing safety.

Furthermore, it is crucial for users to recognize the importance of regular inspection and maintenance of gas hoses. The American Gas Association (AGA) recommends that hoses be visually inspected for any signs of wear, damage, or degradation at least once a month. Any hose that exhibits such issues should be replaced immediately to prevent potential hazards. Training for personnel on proper handling and storage also plays a critical role in maintaining safety; this includes storing hoses away from sharp objects, heat sources, or corrosive chemicals, thereby maximizing their lifespan and performance while minimizing risks.

Maintaining and inspecting your gas hose is critical for ensuring safety and operational efficiency. According to the National Fire Protection Association (NFPA), improper maintenance of gas hoses can be a significant factor in 20% of all gas-related incidents, highlighting the importance of regular inspections. A thorough examination should include checking for wear and tear, leaks, and proper fittings. The American Society of Mechanical Engineers (ASME) recommends conducting these inspections at least once every three months, or more frequently if the hoses are subjected to harsh environments or heavy use. A systematic approach to inspection can significantly reduce the risk of accidents.

Best practices for maintaining gas hoses involve several key strategies. First, always store hoses in a cool, dry place away from direct sunlight and abrasive surfaces, as UV exposure can degrade materials over time. Additionally, it's vital to follow established procedures for cleaning and repairing hoses. According to the Gas Technology Institute, regular cleaning can prevent blockages and prolong the lifespan of the hose.

If any damage is detected during inspections—such as cracks or swelling—replace the hose immediately, as these signs can indicate a compromised structure that may lead to hazardous leaks. Properly training personnel on these maintenance protocols is essential to ensure a safe working environment.

When selecting a gas hose, individuals often make critical mistakes that can compromise safety and functionality. One common error is failing to assess the compatibility of the hose materials with the specific type of gas being utilized. According to the American National Standards Institute (ANSI), using hoses made of incompatible materials can lead to degradation and leaks, posing significant hazards. It's essential to check for certifications such as those from the National Fire Protection Association (NFPA), which outline standards for gas hose materials.

Another frequent mistake is disregarding the pressure rating of the hose. A report by the American Society for Testing and Materials (ASTM) indicates that using a hose with an inadequate pressure rating can lead to catastrophic failures. Users should always consider both the maximum working pressure and the burst pressure of the hose to ensure it can safely handle the demands of their application. Additionally, improper sizing is a prevalent issue; the right diameter is vital for maintaining appropriate gas flow and pressure levels, as undersized hoses can lead to dangerous blockages and backpressure situations. By avoiding these mistakes, individuals can enhance both safety and efficiency in their gas handling operations.