When it comes to plumbing and construction projects, the choice of materials can make a significant difference in both functionality and aesthetic appeal. Among versatile options available, clear PVC pipe stands out for its unique combination of transparency and durability. This material not only facilitates easy monitoring of fluid flow but also integrates seamlessly into various installations, rendering it popular among DIY enthusiasts and professionals alike. In this guide, we will explore essential tips for the perfect installation and maintenance of clear PVC pipe, ensuring that your projects not only perform optimally but also maintain their clarity and integrity over time.

Whether you're installing a new irrigation system, setting up an aquarium, or working on any application that requires reliable piping solutions, understanding the unique properties and techniques for clear PVC pipe is crucial. From selecting the right diameter to employing the proper adhesives and fittings, every aspect of the installation process can impact both the functionality and longevity of your system. Furthermore, regular maintenance practices will help you preserve the clarity and performance of your pipes, avoiding common pitfalls that can arise from neglect. Join us as we delve into the best practices and key considerations for mastering the art of clear PVC pipe installation and maintenance.

Clear PVC pipe is a highly versatile material widely used in various applications due to its unique properties. One of the primary benefits of clear PVC pipe is its transparency, which allows for easy monitoring of fluid flow and potential blockages without the need for additional inspection tools. This characteristic is particularly advantageous in plumbing systems, aquariums, and other fluid transport scenarios where visibility can enhance maintenance and efficiency. Additionally, its chemical resistance makes it suitable for transporting a range of liquids, including those that may be corrosive or require careful handling.

In terms of applications, clear PVC pipe is commonly used in both residential and commercial settings. It is ideal for projects that require aesthetic appeal alongside functionality, such as custom aquariums, hydroponic systems, and various irrigation setups. Its lightweight nature makes it easy to install, while its durability ensures long-lasting performance under various environmental conditions. These attributes make clear PVC pipe a favored choice for professionals and DIY enthusiasts alike, enabling a seamless integration into diverse systems while providing peace of mind regarding maintenance and visibility.

This bar chart illustrates the key benefits of clear PVC pipes, including cost-effectiveness, durability, flexibility, clarity, and chemical resistance. Each attribute is rated on a scale of 1 to 10, showcasing clear PVC pipes as an advantageous choice for various applications.

When it comes to installing clear PVC pipes, having the right tools is essential for achieving a flawless and durable setup. A basic toolkit for clear PVC pipe installation should include a measuring tape for accurate lengths, a pipe cutter for clean cuts, and a deburring tool to remove any rough edges that could affect connections.

These tools ensure that pipes fit together snugly, preventing leaks and promoting a long-lasting installation.

In addition to the basic tools, a good quality primer and solvent cement are crucial for assembling clear PVC pipe systems.

The primer prepares the surfaces for bonding, while the solvent cement creates a strong, water-tight seal. It’s also beneficial to have a hand saw or a jigsaw on hand for slicing through thicker pipes.

Don't forget a pair of safety goggles and gloves to protect yourself during the installation process.

With the right tools and some careful preparation, you can ensure that your clear PVC pipe installation is both effective and reliable.

Installing clear PVC pipes can significantly enhance your plumbing system’s visibility and performance. The first step in this process involves proper measurement and cutting. According to the Plastics Pipe Institute, precise cutting techniques are crucial, as even a small deviation can lead to significant issues such as leaks or improper fittings. Use a pipe cutter for a clean cut, ensuring that the ends are smooth and free of burrs. Measurements should be taken meticulously, with allowances for fittings and angle changes to avoid unnecessary stress on the joints.

Once the pipes are cut, the next step is to prepare the joints for assembly. Cleaning both the exterior of the pipe and the interior of the fittings is essential to promote a solid seal. It is recommended to use a suitable solvent cement, as supported by industry reports indicating that using the right adhesive can increase the strength of the joint by up to 40%. When applying the adhesive, it's important to follow the manufacturer’s guidelines for drying time, as this can affect the overall durability of the installation. Proper installation and maintenance of clear PVC pipes not only prolong their lifespan but also ensure optimal performance in various applications ranging from irrigation systems to plumbing.

| Tip Number | Installation Tip | Maintenance Tip | Common Issue |

|---|---|---|---|

| 1 | Use a proper cutting tool for a clean cut. | Regularly inspect for cracks or discoloration. | Leaking joints due to improper sealing. |

| 2 | Deburr edges after cutting to avoid damage. | Clean with mild soap and water, avoid harsh chemicals. | Blockages caused by debris accumulation. |

| 3 | Dry fit pieces before permanent installation. | Lubricate joints with silicone grease. | Discoloration from UV exposure. |

| 4 | Ensure alignment before sealing joints. | Store pipes away from direct sunlight. | Fragility due to extreme temperature changes. |

| 5 | Use primer and cement suitable for PVC. | Hold pipes in place until cement cures fully. | Inadequate seal causing recurring leaks. |

When it comes to maintaining clear PVC pipes, understanding the proper care can significantly enhance their longevity and reliability. A recent industry report indicates that improper maintenance can reduce the lifespan of PVC pipes by up to 30%. To prevent this, begin with regular inspections to identify any signs of wear, such as discoloration or cracks, which can indicate degradation and necessitate replacement.

One essential maintenance tip is to keep the pipes clean. Regularly flushing the system with water can help remove buildup and prevent clogs that may lead to pressure issues. It's also advisable to avoid exposing clear PVC pipes to direct sunlight for extended periods, as UV rays can weaken the material over time. Consider using protective coverings or relocating the pipes to shaded areas to ensure maximum durability.

Additionally, monitor the temperature of the water flowing through the pipes. Clear PVC is rated for a specific temperature range, and exceeding this can lead to softening and warping. For optimal performance, ensure that the water temperature remains within the recommended limits (usually below 140°F). Implementing these maintenance strategies will not only extend the life of your clear PVC pipes but also ensure they function effectively for years to come.

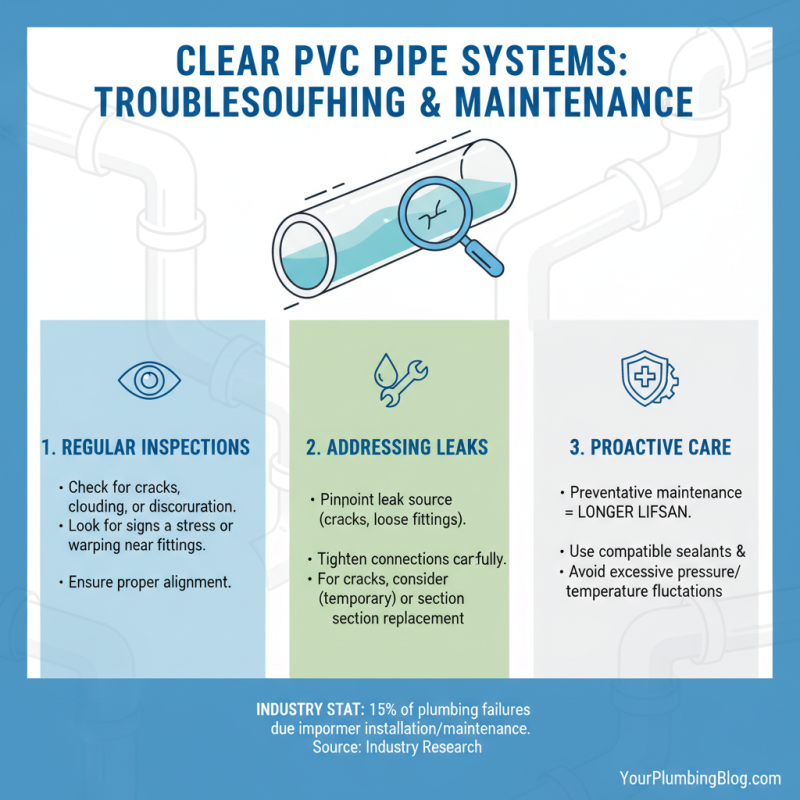

When dealing with clear PVC pipe systems, a solid understanding of troubleshooting common issues is essential for ensuring optimal performance. Regular inspections can help detect cracks or weaknesses in the pipe, which often lead to leaks. According to industry research, approximately 15% of plumbing failures are linked to improper installation or maintenance of piping systems. Being proactive is key to extending the lifespan of your clear PVC installations.

One common issue is cloudiness that can develop over time. This often results from the build-up of particles or minerals within the pipe. To mitigate this, regular cleaning using a non-abrasive pipe cleaner can help restore clarity. Additionally, ensuring that the pipes are not exposed to harsh chemicals during routine cleaning can prevent deterioration. Regularly scheduled maintenance can help catch these issues early, saving time and money in the long run.

For a successful installation and maintenance routine, here are some tips: first, ensure that all joints are properly sealed with high-quality adhesives designed for PVC. Secondly, avoid excessive bending or twisting during installation, which can lead to stress points. Lastly, consider using UV-resistant coatings or shades if the pipes are exposed to direct sunlight, as prolonged exposure can impact their durability. By taking these precautions and addressing issues proactively, you can maintain a clear and efficient PVC pipe system.