Choosing the right 2 discharge hose is crucial for ensuring efficiency and effectiveness in various industrial and commercial applications. With a multitude of options available in the market, it can be overwhelming to identify the hose that best suits your specific needs. Whether you're involved in agriculture, construction, or wastewater management, selecting a durable and reliable 2 discharge hose can significantly impact the performance of your operations.

In this article, we will explore ten essential tips to guide you in making an informed decision when purchasing a 2 discharge hose. From understanding the materials used in hose construction to considering the necessary pressure ratings and environmental factors, our comprehensive guide aims to equip you with the knowledge required to choose wisely. With the right hose at your disposal, you can enhance productivity while minimizing the risk of leaks or hose failures, contributing to a safer and more efficient working environment.

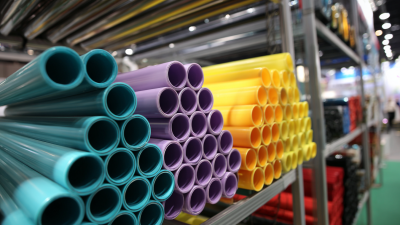

When selecting a discharge hose, the material from which it is made is of paramount importance. Different materials offer various benefits and drawbacks that can significantly impact the effectiveness and longevity of the hose. For instance, rubber hoses are known for their durability and resilience against abrasion, making them ideal for heavy-duty applications. On the other hand, PVC hoses are lightweight and more cost-effective, but may not withstand extreme temperatures or harsh chemicals.

Additionally, consider the specific pressures and temperatures that the discharge hose will be exposed to during operation. High-temperature applications may require hoses made from specially formulated materials that resist heat degradation. Likewise, if the hose will be used to transport corrosive liquids, it’s essential to select a material that is chemically resistant to avoid premature failure. Understanding the environmental factors—such as UV exposure or exposure to ozone—can also inform your choice, ensuring that the discharge hose you select will perform reliably over time.

| Factor | Description | Material Options | Best Use Cases |

|---|---|---|---|

| Temperature Resistance | Ability to handle high or low temperatures without degradation. | PVC, Rubber, Silicone | Agricultural applications, industrial settings, food processing. |

| Chemical Compatibility | Resistance to various chemicals, ensuring longevity and safety. | Polypropylene, Teflon | Chemical processing, waste management. |

| Pressure Rating | Maximum pressure the hose can handle without failure. | Rubber, Reinforced PVC | High-pressure applications, irrigation systems. |

| Flexibility | Ease of movement and handling without kinking. | Rubber, Polyurethane | Construction sites, landscaping. |

| Diameter | Size of the hose affects flow rate and pressure. | Varies (typically 1" to 6") | Water transfer, pumps. |

| Length | Consideration of distance for application. | Custom lengths available | Sump pumps, agricultural irrigation. |

| Weight | Can influence handling and installation. | Lightweight composites, heavier rubber | Portable applications, fixed installations. |

| UV Resistance | Ability to withstand degradation from sunlight. | Polyethylene, PVC with UV additives | Outdoor use, sun-exposed applications. |

| Cost | Consider budget versus quality and performance. | Varies widely | All applications, personal preferences. |

When selecting the right 2-inch discharge hose, understanding the diameter's impact on flow rate efficiency is crucial. The diameter directly influences the volume of water that can pass through the hose per minute. A wider diameter allows more fluid to flow, which is essential in applications where quick drainage or high flow rates are required. According to a market report, appropriately sizing hoses can optimize not only water usage but also energy costs associated with pumping. This underscores the importance of considering not just the diameter but also the application specifics before making a purchase.

When selecting the right 2-inch discharge hose, understanding the diameter's impact on flow rate efficiency is crucial. The diameter directly influences the volume of water that can pass through the hose per minute. A wider diameter allows more fluid to flow, which is essential in applications where quick drainage or high flow rates are required. According to a market report, appropriately sizing hoses can optimize not only water usage but also energy costs associated with pumping. This underscores the importance of considering not just the diameter but also the application specifics before making a purchase.

Here are some essential tips for selecting the right hose: First, evaluate the required flow rate for your specific application. If you need to move large volumes of water rapidly, opting for a hose with a larger diameter can enhance efficiency. Second, consider the material of the hose, as it can affect durability and performance. For instance, some materials can handle higher pressures, which is necessary for certain tasks. Lastly, always verify compatibility with your existing systems to ensure a seamless connection. Making informed decisions based on these guidelines will lead to better outcomes and reduced operational challenges.

When selecting a discharge hose, evaluating its temperature and chemical resistance is crucial to ensure optimal performance and longevity. Different applications demand hoses that can withstand varying temperatures; for instance, a hose used in hot water discharge must be rated for high-temperature scenarios to prevent failure or deformation. Always check the manufacturer’s specifications regarding the maximum and minimum temperature the hose can handle, as well as its flexibility under thermal stress.

Additionally, chemical resistance is paramount in industries that deal with corrosive substances. The material of the discharge hose must be compatible with the chemicals it will transport to avoid degradation that can lead to leaks or bursts. Common materials like rubber, PVC, and polyurethane each have unique properties and resistance levels to different chemicals. Conducting thorough research and consulting manufacturer data sheets can guide you in choosing a hose that will not only meet regulatory standards but also safeguard your operations by minimizing the risks of chemical reactions and breakdowns during usage.

When choosing the right discharge hose, determining the ideal length is crucial to ensure efficient operation and optimal performance. The length of the hose directly affects the water flow rate and pressure, which are vital for applications such as dehumidification and water removal from pools or basements. According to industry reports, using a hose that is too long can result in significant pressure losses, sometimes exceeding 20% depending on the hose diameter and material. Therefore, measuring the distance from the water source to the discharge point is essential to prevent cumbersome bends and kinks that may impede flow.

Additionally, the required length may vary based on specific uses—whether you're pumping water from a pool or handling excess moisture in a basement. For instance, in testing various dehumidifiers, it was noted that using properly sized discharge hoses greatly improved moisture removal efficiency, contributing to better air quality and a reduction in mold growth. A well-chosen hose not only streamlines your processes but also enhances the longevity and effectiveness of the pumping equipment. Thus, taking the time to measure and select the right length can lead to substantial benefits in maintenance and operation efficiency.

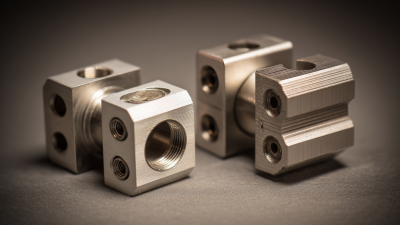

When selecting a 2 discharge hose, ensuring compatibility with your pump system and accessories is crucial to achieving optimal performance. According to the Hydraulic Institute, the efficient transfer of fluids can be significantly impacted by the hose's diameter, material, and pressure rating. For instance, using a hose with a larger diameter than required can lead to increased flow and reduced pressure, which may not be suited for all applications. Conversely, a hose that is too small may restrict flow and cause overheating, damaging both the hose and the pump.

It’s also critical to consider the hose material when assessing compatibility. A study from the American Society for Testing and Materials (ASTM) indicates that certain materials like PVC or rubber can withstand various chemical compositions, but if the discharge hose is incompatible with the fluid being transported, it could degrade quickly, leading to failures. Furthermore, ensure that fittings and couplings match the specifications of your pump system to avoid costly leaks or inefficiencies. By focusing on these compatibility factors, you can select a discharge hose that not only meets your current needs but also aligns with your long-term operational efficiency.