In the world of plumbing, having a solid understanding of steel pipe fittings is crucial for ensuring both the efficiency and reliability of any piping system. As we venture into 2023, the relevance of steel pipe fittings continues to grow, thanks to their durability and versatility in various applications. From residential plumbing to industrial environments, steel pipe fittings play a vital role in connecting different sections of piping, controlling flow, and preventing leaks.

This article aims to highlight the top 10 steel pipe fittings that every plumber should be well-versed in. These fittings not only cater to a wide range of plumbing needs but also contribute to the overall safety and integrity of plumbing systems. By familiarizing oneself with these essential components, plumbers can enhance their skills, streamline their installations, and address common plumbing challenges with confidence. Whether you're a seasoned professional or a newcomer to the plumbing industry, understanding these steel pipe fittings can significantly elevate your expertise and service quality.

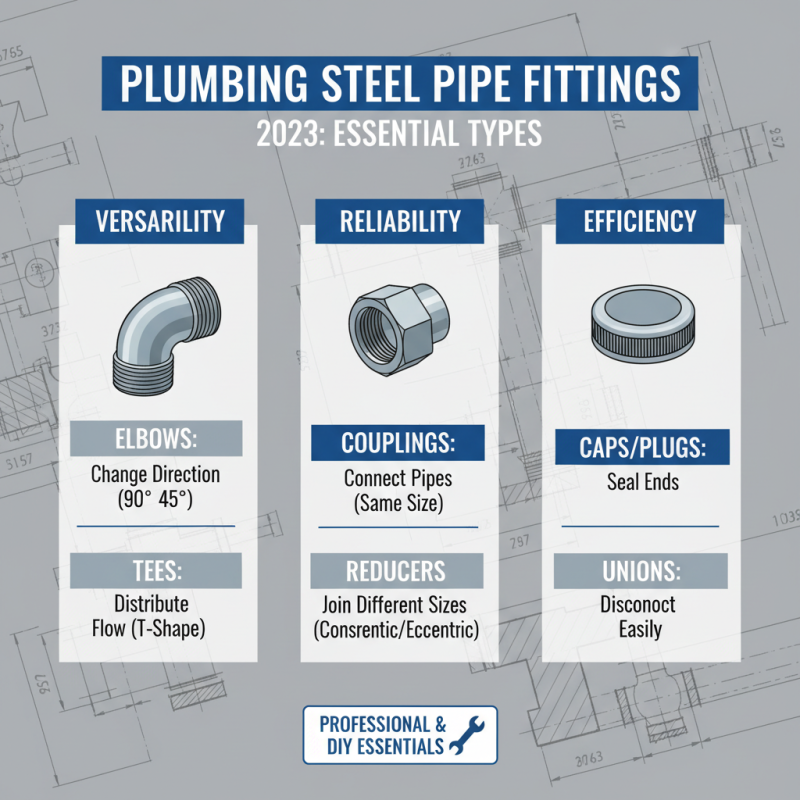

In the world of plumbing, understanding the various types of steel pipe fittings is essential for both professionals and DIY enthusiasts alike. In 2023, certain fittings stand out for their versatility and reliability. From elbows to tees, each fitting serves a unique purpose, making them indispensable tools in any plumber’s arsenal. Familiarity with these fittings can significantly enhance efficiency in installation and repair tasks.

When working with steel pipe fittings, consider the material’s compatibility with the piping system. For long-term durability, it’s crucial to assess the environment where the fittings will be used. Always opt for fittings that can withstand the pressures and temperatures of your specific application. Regularly check for wear and tear to avoid leaks, as even minor damage can lead to major plumbing issues.

Tips: Always use the correct tools for installation to prevent damage to the fittings and ensure a secure seal. Additionally, when joining fittings, apply the appropriate sealant to avoid leaks. Lastly, stay updated on any new materials or technologies in the plumbing industry that could improve the performance and longevity of your installations.

Steel pipe fittings play a crucial role in the functionality and durability of plumbing systems. In 2023, the construction and plumbing industries continue to emphasize the importance of these fittings, as they are responsible for connecting pipes, ensuring smooth fluid flow, and accommodating changes in direction or pipe size. According to a recent industry report by the American Society of Plumbing Engineers, over 70% of plumbing failures are attributed to subpar fittings and connections. Properly selected steel fittings not only enhance the longevity of plumbing systems but also improve overall efficiency and reduce maintenance costs.

When choosing steel pipe fittings, it's essential for plumbers to consider various factors such as pressure ratings, temperature tolerances, and corrosion resistance. For example, ASTM standards indicate that stainless steel fittings are often preferred for high-pressure applications due to their strength and resistance to corrosion. Additionally, investing in quality fittings can prevent leaks, which according to the Environmental Protection Agency, can waste approximately one trillion gallons of water annually in the United States alone.

Tips: Always ensure that you are using the right fitting for the specific application to avoid costly repairs in the future. Regularly inspecting connections for signs of wear can help catch issues early. Lastly, staying updated with industry standards and advancements in manufacturing practices will ensure that your plumbing systems are not only reliable but also compliant with current regulations.

In 2023, understanding the key types of steel pipe fittings is crucial for plumbers to ensure effective plumbing solutions. Steel pipe fittings come in various shapes and sizes, each designed for specific applications. Among the most common types are elbows, tees, and couplings. Elbows are used to change the direction of the pipe, typically at a 90 or 45-degree angle, making them essential for navigating around obstacles. Tees allow for branching off in multiple directions, perfect for connecting different pipelines. Couplings, on the other hand, are vital for joining two pipes together, maintaining a seamless flow.

When working with steel pipe fittings, remember that the type of fitting you choose can greatly affect the overall efficiency of your plumbing system. Here are some tips to consider: 1) Always assess the pressure and temperature ratings of the fittings to ensure they meet your system's requirements. 2) Keep in mind the potential for corrosion; using galvanized steel fittings can provide an added layer of protection. 3) Proper installation is key—using the right tools and techniques will prevent leaks and prolong the lifespan of the fittings.

In addition to these common fittings, there are other specialized options like reducers and caps that serve specific functions in plumbing systems. Reducers help to connect pipes of different diameters, while caps are used to close off the end of a pipe. Knowing when and how to use these fittings effectively can streamline your plumbing projects and ensure a secure and functional system.

| Fitting Type | Description | Applications | Material |

|---|---|---|---|

| Elbow | Used to change the direction of piping. | Plumbing, HVAC systems | Carbon Steel |

| Tee | Allows branching off from a main line. | Water supply, drain systems | Stainless Steel |

| Coupling | Connects two pieces of pipe. | Water and gas lines | Black Steel |

| Cap | Seals the end of a pipe. | Hydraulic systems | Galvanized Steel |

| Union | Easy disconnection of pipe sections. | Heating systems | Stainless Steel |

| Reducer | Changes pipe diameter. | Fire protection systems | Carbon Steel |

| Bend | Offers a gradual change in direction. | Waste water systems | Black Steel |

| Flange | Provides a connection point between pipes. | Industrial piping | Carbon Steel |

| Plug | Closes off a pipe for maintenance. | Repair work | Stainless Steel |

| Cross | Connects four pipe sections. | Complex plumbing layouts | Galvanized Steel |

When it comes to steel pipe fittings, industry standards play a crucial role in ensuring

quality and safety in plumbing applications. These standards govern the specifications of materials, dimensions, and performance characteristics, ensuring that the

fittings can withstand the pressures and conditions they will encounter. Understanding these standards is essential for plumbers who seek to use fittings that not

only meet regulatory requirements but also provide durability and reliability in their projects.

The specifications for steel pipe fittings typically include details such as the types of materials used, the heat treatment processes, and the testing methods that

ensure compatibility with various fluids and gases. Fittings must be robust enough to handle different pressures and temperatures, making adherence to these standards

a fundamental aspect of the plumbing industry. By familiarizing themselves with the standards applicable to different types of fittings, plumbers can make informed

decisions that enhance the safety and efficiency of their installations.

In 2023, the market for steel pipe fittings is witnessing a notable transformation driven by innovative technologies and evolving consumer demands. Manufacturers are increasingly focusing on advanced materials that enhance durability and resistance to corrosion, contributing to the longevity of plumbing installations.

The integration of smart manufacturing techniques, including automation and precision fabrication, is streamlining production processes, thus improving the overall quality and availability of steel pipe fittings in the market.

Moreover, sustainability has become a key consideration in the development of steel pipe fittings. The industry is witnessing a higher demand for eco-friendly solutions, prompting manufacturers to adopt recycling practices in their production lines and utilize materials with lower environmental impacts. This trend reflects a broader shift towards sustainability in construction and plumbing sectors, where efficient resource management and reduced waste are becoming paramount. As the focus on both innovation and environmental responsibility evolves, plumbers must stay informed about these trends to ensure they are equipped with the most effective and sustainable fittings for their projects.

In 2023, understanding steel pipe fittings has become essential for plumbers due to their critical role in plumbing systems. This article highlights the top ten steel pipe fittings that every plumber should be familiar with, providing an overview of their applications and importance. It also dives into industry standards, ensuring quality and specifications are met for optimal performance.

Additionally, the article discusses emerging trends in steel pipe fittings, showcasing innovations and market demands that shape the industry. The material composition of these fittings significantly impacts their performance, making knowledge of these factors crucial for effective plumbing solutions. Plumbers who stay informed about these aspects will be better equipped to tackle diverse plumbing challenges.